2025 Volume 73 Issue 1 Pages 18-24

2025 Volume 73 Issue 1 Pages 18-24

This study investigates the influence of needleless versus needle-based electrospinning methods on the fiber diameter of polyamide 6 (PA6) nanofibers under comparable conditions, with an emphasis on potential pharmaceutical applications. Additionally, it examines how varying solvent systems impact fiber diameter specifically in needleless electrospinning. In this study, it was found that fibers produced by the needleless method were thicker compared to those produced by the needle-based method, a trend attributable to the specific solution characteristics and parameter settings unique to this study. Notably, a 2 : 1 acetic acid : formic acid solvent mixture yielded the largest fiber diameters among the solvent systems assessed for needleless electrospinning. These results underscore the potential of PA6 nanofibers in pharmaceutical applications, suggesting that further optimization of electrospinning conditions could enhance their suitability. The study also discusses the implications of scale-up production using needleless technology, highlighting its viability for industrial applications over single-needle electrospinning.

Electrospinning is a versatile method for fabricating nanofibers with controlled properties and is widely used in air and water filtration, membrane making, and insulator and capacitator design. This study addresses the differences between needleless and needle-based electrospinning methods, specifically focusing on the fiber diameter. Polyamide 6 (PA6; Table 1) was selected owing to its chemical stability and mechanical properties.1) Despite several previous studies, there remains a gap in directly comparing these two methods, especially in terms of the effects of solvents on fiber diameter.1,2)

|

The pharmaceutical and chemical applications of PA6 nanofibers are significant due to their excellent mechanical properties and biocompatibility. They have been investigated for use in drug delivery systems by providing controlled release of therapeutic agents, tissue engineering, biomedical applications, and filtration.3–9) They are also used in wound dressings because they support cell growth and provide a barrier against infections. Producing PA6 nanofibers with specific diameters and morphologies using different electrospinning methods can significantly impact their performance in these applications.

A critical factor in electrospinning for pharmaceutical applications is production scale-up. Single-needle electrospinning, while providing precise control over fiber morphology, is limited in its production rate, making it less suitable for industrial-scale applications. Contrarily, Elmarco’s Nanospider needleless electrospinning technology allows for higher throughput, making it more practical for large-scale production. Understanding the differences between these methods and their implications for fiber characteristics is essential for optimizing production of PA6 nanofibers for pharmaceutical and medical applications. This study aims to investigates these complexities.

Polyamide 6 was purchased from Polysciences, Inc. (MW = 35000, U.S.A., Lot # A834426). Formic acid was obtained from FUJIFILM Wako Pure Chemical Corporation (90%, Japan, Lot # ACQ1043). Acetic acid was procured from Wako Pure Chemical Corporation (Anhydrous, Japan, Lot # ACL6218).

MethodsNeedle-Based ElectrospinningThe in-house electrospinning machine of Gifu Pharmaceutical University powered by a high voltage unit (Matsuda, Japan, S/N 22K15263) was used to obtain the fibers. The voltage was set to a maximum of 30 kV, with a tip-to-collector distance of 15 cm, using 22-gauge stainless steel needles. Furthermore, 5-mL Terumo® syringes with non-beveled needles were used to feed the system at a ratio of 1.0 mL/h. Siliconized papers were used as collectors, and the relative humidity and temperature of the electrospinning environment were regularly monitored. Each electrospinning trial required approximately 5 h, accounting for the feed rate and the sample solution volume.

Needleless ElectrospinningElmarco® (NS Lab, Czech Republic) Nanospider electrospinning machine was used in needleless experiments. All trials were conducted at a carriage rate of 150.0 mm/s, polypropylene fabric substrate speed of 10.0 mm/min, and applied voltage of 70.0 kV. The electrode distance was adjusted to 180.0 mm, and the distance between the collecting electrode and substrate was maintained at 30.0 mm. The orifice size for this set of trials was 0.6 mm. Relative humidity and temperature were recorded for each experiment, and a 10 mL solution was used for each trial. The electrospinning trials were performed until the entire 10 mL sample solution was electrospun, which took approximately 20 min. In both the needle-based and needle-less methods, the produced fiber mats were placed under a fume hood for 24 h to allow residual solvents to evaporate fully.

Sample PreparationSingle-solvent solutions of formic acid and mixed-solvent solutions of acetic : formic acid (2 : 1) were prepared at 80 °C and agitated at 300 rpm via magnet stirring. Each solution was cooled to room temperature in 30 min. A single-solvent solution of acetic acid was prepared at 150 °C and agitated at 300 rpm using magnet stirring. Notably, PA6 is insoluble in pure acetic acid at temperatures <100 °C. Thus, the single-solvent solution of acetic acid did not go through a cooling period and was electrospun directly at a solution temperature of 100 °C.

Analysis and MeasurementsScanning Electron MicroscopyScanning Electron Microscopy (SEM) (JCM-700, JEOL, Japan, S/N MP 1240005750575) was used to observe the morphology of the obtained nanofiber mats. Each sample was platinum-sputtered to increase the conductivity, and the SEM landing voltage was adjusted to 15 kV. JEOL ruler software was used to measure the fibers’ diameter. One hundred spots were selected from each nanofiber sample at a magnification of 5000× and the average diameter was reported.

Table 1 lists the electrospinning parameters and solution characteristics of the needle-based trials. The concentration of the sample solutions gradually increased, and the morphology and diameter of the fibers were observed. Figure 1 shows the SEM images of each sample.

All images were captured at a 5000× magnification, with a landing voltage of 15 kV, and a scale bar of 5 µm (except for S1, which was captured with a 2 µm scale bar).

Fibers with smooth surfaces were obtained. They were mostly branchless, bead-free, and non-ribbon shaped, indicating a high level of control over fiber morphology via the needle-based tecnique. Increasing the solution percentage resulted in fibers with larger diameters. Moreover, high humidity resulted in larger morphologies in our fiber mats. The needle-based setup is shown in Supplementary Fig. S1.

The Morphology Study of the Needleless NanofibersTable 2 lists the electrospinning parameters of the needleless trials. Various solution concentrations were used and the characteristics of the produced fibers were examined. Figure 2 shows the SEM images illustrating the fibers’ morphologies.

| Sample Name | Conc.a) (w/w) % | Solvent system | RH (%)b) | Temp. (C°)c) | Av.d) D.e) ± S.D.f) (nm) |

|---|---|---|---|---|---|

| S1 | 11 | Formic acid | 49 ± 5 | 27 ± 1 | 61 ± 41.95 |

| S2 | 12 | Formic acid | 50 ± 5 | 27 ± 1 | 95 ± 31.94 |

| S3 | 13 | Formic acid | 48 ± 5 | 27 ± 1 | 128 ± 48.16 |

| S4 | 15 | Formic acid | 44 ± 5 | 27 ± 1 | 206 ± 38.30 |

| S5 | 15 | Formic acid | 47 ± 5 | 24 ± 1 | 234 ± 26.01 |

| S6 | 15 | Formic acid | 43 ± 5 | 24 ± 1 | 217 ± 49.39 |

| S7 | 15 | Formic acid | 50 ± 5 | 26 ± 1 | 221 ± 27.60 |

| S8 | 20 | Formic acid | 45 ± 5 | 26 ± 1 | 345 ± 57.25 |

| S9 | 20 | Formic acid | 40 ± 5 | 25 ± 1 | 326 ± 55.98 |

| S10 | 20 | Formic acid | 50 ± 5 | 26 ± 1 | 352 ± 131.85 |

a) Concentration. b) Relative humidity. c) Temperature. d) Average. e) Diameter. f) Standard deviation.

All images were captured at a 5000× magnification, with a landing voltage of 15 kV, and a scale bar of 5 µm.

Fiber mats with various morphologies were obtained in the needleless trials. Notably, the fiber manufacturing mechanism in needleless electrospinning provides a faster production rate than traditional needle-based methods.9,10) The equipment used to produce such nanofiber mats is shown in Supplementary Fig. S2. The Elmarco Nanospider electrospinning machine employs a unique needle-free technology for nanofiber production, utilizing a rotating electrode system. As the electrode rotates, it picks up a thin layer of polymer solution from the reservoir, forming a film on its surface. A high voltage applied between the rotating electrode and the grounded collector creates a strong electric field, inducing charges on the polymer film. When the electrostatic forces overcome the surface tension, Taylor cones form, and the polymer solution is ejected as jets. These jets elongate and solidify as the solvent evaporates, forming nanofibers that are collected on a grounded collector, resulting in a non-woven mat of nanofibers.11,12)

By comparing Tables 2, 3, it can be inferred that using PA6 at the same concentration results in fibers with larger diameters in the needleless system compared with the needle-based system. This difference may be because, in the traditional nozzle-based system, there is only one feed rate controlling the solution loading. Conversely, the needleless system features multiple spots on a single rotating electrode, each containing the solution, leading to the formation of multiple Taylor cones and consequently larger fiber diameters.

| Sample Name | Conc.a) (w/w) % | Solvent system | Ratio | RH (%)b) | Temp. (C°)c) | Av.d) D.e) ± S.D.f) (nm) |

|---|---|---|---|---|---|---|

| S1´ | 15 | Formic acid | 1 | 46 | 27 | 256 ± 57.6 |

| S2´ | 15 | Acetic acid | 1 | 46 | 27 | 267 ± 64.07 |

| S3´ | 15 | AA : FA* | 2 to 1 | 47 | 27 | 241± 23.44 |

| S4´ | 25 | Formic acid | 1 | 48 | 26 | 473 ± 106.42 |

| S5´ | 20 | AA : FA | 2 to 1 | 50 | 24 | 396 ± 89.10 |

| S6´ | 20 | Formic acid | 1 | 49 | 25 | 375 ± 33.12 |

| S7´ | 15 | Formic acid | 1 | 48 | 26 | 293 ± 21.97 |

| S8´ | 25 | AA : FA | 2 to 1 | 43 | 27 | 568 ± 127.8 |

| S9´ | 15 | AA : FA | 2 to 1 | 47 | 27 | 256 ± 19.2 |

a) Concentration. b) Relative humidity. c) Temperature. d) Average. e) Diameter. f) Standard deviation. *Acetic acid : formic acid.

In the needle-based electrospinning method, the fiber diameter was significantly affected by the concentration of the polyamide 6 solution and environmental conditions such as relative humidity and temperature. As shown in Table 2 and Fig. 1, increasing the polyamide 6 concentration resulted in thicker fibers. The relative humidity also plays a significant role, with higher humidity leading to larger fiber diameters.

Conversely, as shown in Table 3 and Fig. 2, the needleless electrospinning method produces larger fiber diameters at the same polyamide 6 concentration. This is due to multiple Taylor cones on a rotating electrode, which increase the feed rate and result in larger fibers. The SEM images reveal that the needleless method produced fibers with various morphologies, although the control over fiber uniformity is less precise than that of the needle-based method.13–16) Figure 3 illustrates a comparison between the diameters of the fibers obtained using each method with the same concentration of the solution samples.

The name of samples used for each measurement are shown at the top of its respective column.

Another notable observation in both Fig. 1 (S8, S10) and Fig. 2 (S2, S5, S8) is the presence of ribbon-shaped or flattened fibers. These fiber formations arise from the interplay between solution properties, environmental conditions, and process parameters. A primary factor is the solvent system and its evaporation rate; when evaporation occurs unevenly or too slowly, the electrospun fibers may collapse as they approach the collector, forming non-uniform, ribbon-like structures. High solution concentrations also contribute, as increased viscosity produces thicker, more pliable fibers that may not maintain a rounded profile upon deposition.

Additionally, polymer molecular interactions and the specific drying environment play a role. For instance, high humidity (the trails were performed in July in the coastal city of Fukui where precipitation is above 90% all the summer) can slow evaporation and lead to fiber collapse, especially in hydrophilic polymers. Furthermore, if the voltage and distance between the needle and collector are not optimized, excessive fiber stretching may occur, resulting in flattened fibers upon landing. These flattened structures could impact the mechanical properties and porosity of the mat, affecting its performance in applications that depend on consistent fiber morphology.

Solvent SystemsThe choice of a solvent system significantly affects the fiber diameter in the needleless electrospinning method. Among the solvent systems tested, the acetic acid : formic acid (2 : 1) mixture produced the thickest fibers. This can be explained by the combined effects of solvent properties and electrospinning parameters. The high boiling point of acetic acid and its interaction with formic acid may lead to slower evaporation rates, resulting in thicker fibers.12,14,16) Figure 4 presents a comparative analysis of different solvent systems at various concentrations.

Bars represent the mean values of the samples (n = 100). Standard deviations are indicated by the dotted lines of each column’s respective line graph.

An advantage of the needleless electrospinning method is the faster production rate compared with the traditional needle-based method. Our needle-less setup completed the entire trial in under 20 min for a 10 mL sample solution. In contrast, the needle-based system required approximately 5 h to electrospin a 5 mL sample, despite a relatively high feed rate of 1 mL/h. The Elmarco Nanospider machine used in this study allows for continuous nanofiber production with a rotating electrode system, which is more efficient than the single-needle setup. Notably, increasing the orifice size allows a greater volume of polymer solution to be deposited onto the wire per unit time, resulting in a thicker polymer layer on the rotating electrode and enabling faster production rates. However, the orifice size must be carefully adjusted relative to the solution viscosity to maintain a consistent polymer layer on the rotating electrode.

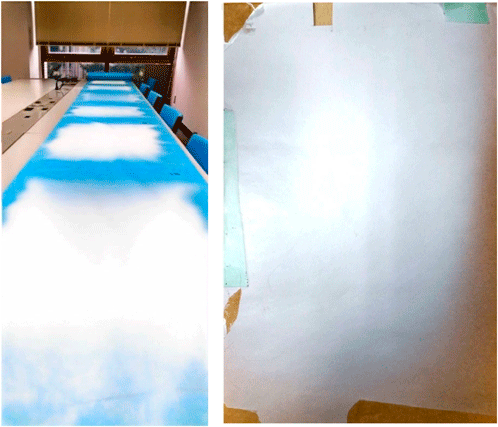

Furthermore, In the needle-less setup utilized in this study, collector materials can be extended up to 100 m, allowing for continuous production of fiber mats with various polymer solutions. Conversely, in the needle-based electrospinning setup, only a single small collector piece can be used per trial, necessitating removal and replacement for each subsequent polymer solution. Figure 5 visually illustrates the collector systems employed in both the needle-based and needle-less setups, highlighting these operational differences. These features make the needleless method more suitable for industrial-scale production where high throughput is required.

The findings of this study highlight the impact of manufacturing processes and solvent selection on the morphology of polyamide 6 nanofibers. The needleless method yielded thicker fibers, which may present potential advantages for applications that could benefit from enhanced and robust mechanical properties. Conversely, the needle-based method may provide finer control over fiber diameter and morphology. However, additional studies would be necessary to substantiate the suitability of these fibers for specific applications in fields such as pharmaceuticals or biomedical engineering.

Future work should focus on optimizing the electrospinning parameters for both methods to achieve the desired fiber characteristics. Additionally, exploring other solvent systems and their combinations could provide further insights into controlling fiber diameter and morphology. The development of hybrid electrospinning methods combining the advantages of the needleless and needle-based methods could also be a promising area of research.15,16) Furthermore, investigating the biocompatibility and drug release profiles of PA6 nanofibers produced using different electrospinning methods may enhance their applicability in the pharmaceutical field.

This study provides a comprehensive comparison between needle-based and needleless electrospinning methods for the production of polyamide 6 nanofibers. Our findings reveal that although the needle-based method offers superior control over fiber diameter and morphology, the needleless method achieves significantly higher production rates. The needleless method, utilizing an acetic acid : formic acid (2 : 1) solvent system, produces thicker fibers, which is advantageous for applications requiring enhanced mechanical properties. On the other hand, these results are conclusions based on the specific conditions of this experiment, and different raw materials or solvents for the nanofibers may lead to different outcomes. Furthermore, by optimizing the experimental conditions and spinning environment (such as temperature and humidity), it is highly possible to achieve precise control over fiber diameter and morphology in the needleless method, allowing for the production of high-quality fibers; indeed, there are numerous reports supporting this.

These results underscore the importance of selecting an appropriate electrospinning method based on specific application requirements. For industrial-scale production where throughput is critical, the needleless method is more efficient. Conversely, for applications requiring precise control over fiber characteristics, the needle-based approach is more suitable.

Future research should focus on optimizing the parameters of both methods to further refine the fiber characteristics. Additionally, exploring new solvent systems and hybridizing both methods may offer novel solutions, enhancing the versatility and applicability of electrospun polyamide 6 nanofibers in various fields, including air and water filtration.

This work was supported by JST SPRING, Japan Grant Number JPMJSP2142. The Laboratory of Nanofiber Technology (Gifu Pharmaceutical University) is an endowment laboratory, supported with an unrestricted grant from Mitsubishi Chemical Corporation.

The Laboratory of Nanofiber Technology (Gifu Pharmaceutical University) is an endowment laboratory, supported with an unrestricted grant from Mitsubishi Chemical Corporation.

KH reports a relationship with Mitsubishi Chemical Corporation that includes employment.

Data will be made available on request.

This article contains supplementary materials.